Process

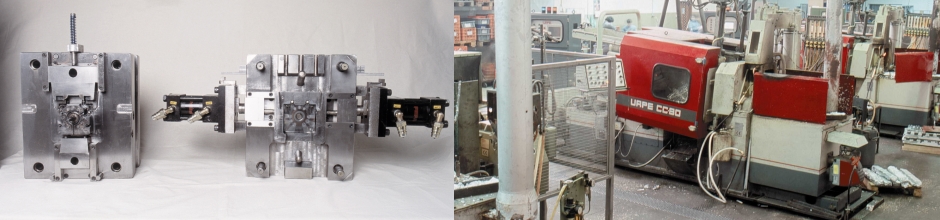

Pressure die casting is the way Someil processes Zamak and is the fastest net shape forming process, allowing precise and cost effective production.

Tolerances: 0,02mm em 1mm

Wall Thickness >= 1,5mm

Average tooling life: 1 million shots

Production rate: 100-400 cycles / hours

Die casting may be followed by operations such as threading, boring and grinding. Once the parts are grinded they can be sold or they can be painted (outsourcing) or electroplated

Electroplating is the process to obtain metallic finishing. It has an initial deposit of copper to protect the zinc substrate, followed by a layer of nickel for corrosion resistance. Other metals, such as chromium and gold can then be plated over the Cu/Ni layer.

Contacts

AddressSOMEIL - Soc. Metais Injectados, Lda.

Campos, Apartado 60

2405-009 Maceira LRA

Portugal

+351 244 770 340

Emailgeral@someil.pt

GPS Coordinates: 39.6833,-8.9145